For the past month, half of our team has been in Shenzhen full-time to ensure quality on the deliveries, while the other half has been in Toronto, diligently preparing our support systems, to be in shipshape once you receive and start using Nora.

We have made it our mission to personally visit and inspect the process at every step of the way—from vendors, to the assembly line, to Quality Assurance and the shipping facility. This has been a worthwhile effort. As with any first production run, there are a number of minor and major issues to address on a daily basis, across the web of vendors and logistics.

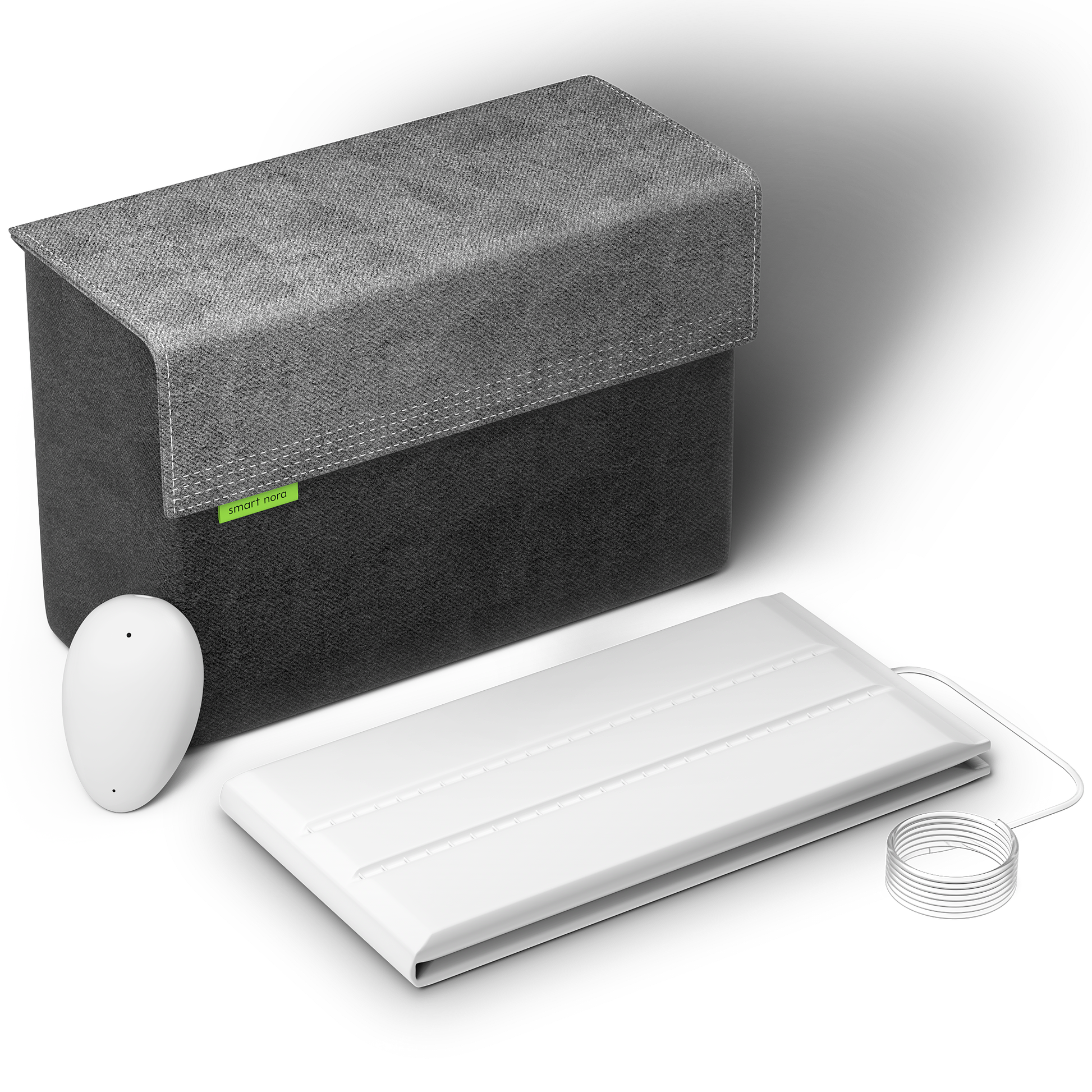

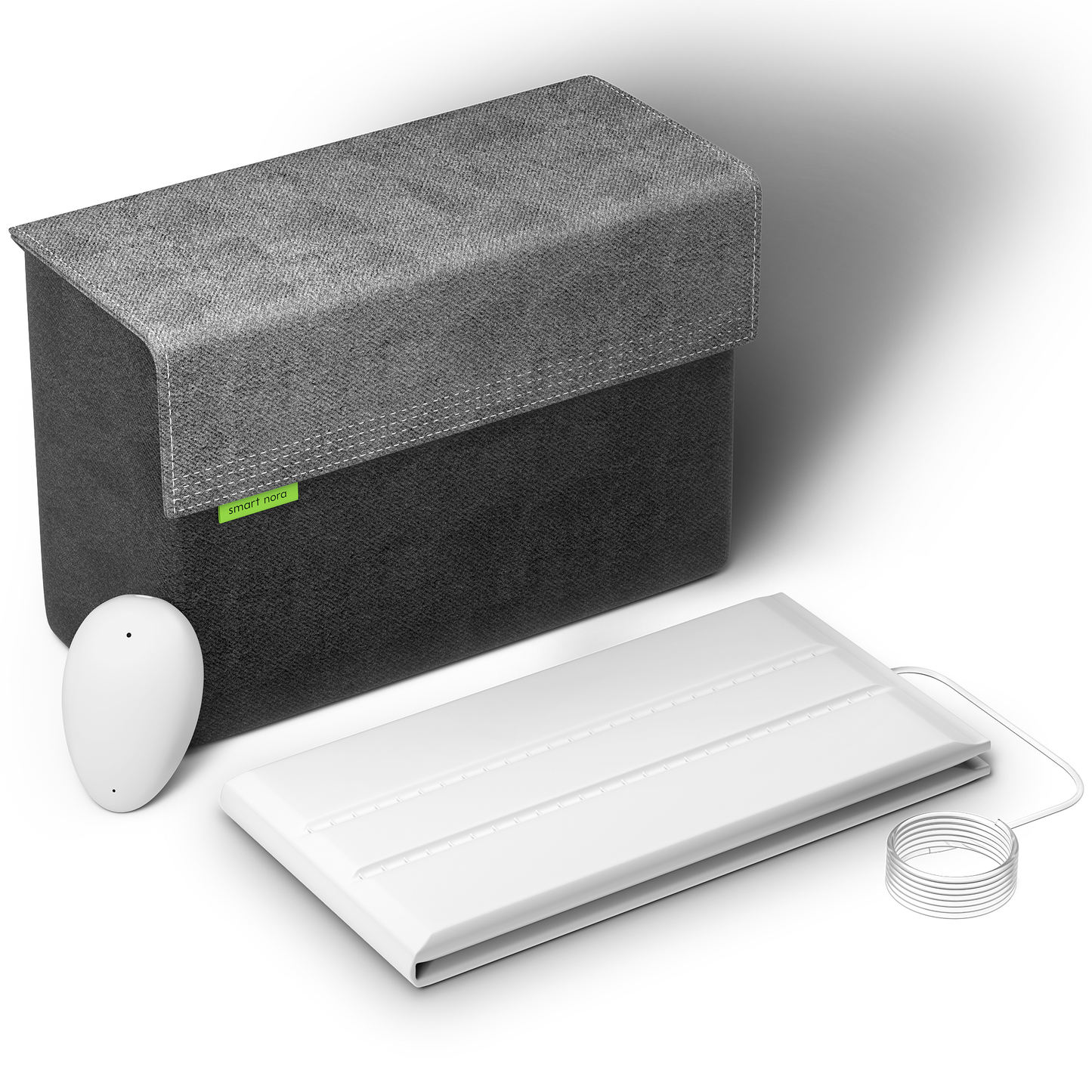

As we ship 12 TONS of Nora's around the world, we are excited to share with you some of the pictures from this process. You can also check out our Instagram for daily images.

Production Update

Here’s a snapshot of our production progress and bringing together a year of designing, planning and coordination:

-

PCBs are all printed and tested.

-

All plastic parts have been produced and coated with the inside paint layer that masks light leaks.

-

Assembly of all inflatable and moving parts, and electronics in plastics is ahead of schedule.

-

We have received all of the print pieces: the pristine white Nora packages and our user manuals.

-

We worked closely with our vendor making your cozy portable bags to ensure the process was fully streamlined.

-

We have tested our shipping and logistics by shipping some test units to different countries. From these early tests, we have received feedback that customs officials are opening some of the packages for inspection. This is a common safety practice and is beyond our control. We apologize in advanced if the customs officials do not pack the units back together in the same orderly manner, and with the level of attention we had when packing them for you at the factory.

BASE UNITS ASSEMBLED AND TESTED